In the heart of every modern manufacturing facility lies a silent revolution—one measured not in decibels but in micrometers, not in horsepower but in hertz. Industrial sensor accuracy has emerged as the unsung hero of Industry 4.0, transforming manufacturing floors from chaotic workshops into precisely orchestrated symphonies of efficiency. The quest for perfection in measurement has become the differentiator between industry leaders and followers, making sensor accuracy not just a technical specification but a strategic business advantage.

Modern Industrial sensors have evolved far beyond simple detection devices. Today’s high-accuracy sensors can detect variations as subtle as 0.001 millimeters, temperature fluctuations of 0.1°C, or pressure changes equivalent to a feather’s touch. This incredible precision enables manufacturing processes that were once considered impossible—from manufacturing microchips with nanometer-scale features to producing medical devices with life-saving tolerances. The implications extend beyond mere production quality; they redefine what’s achievable in modern engineering.

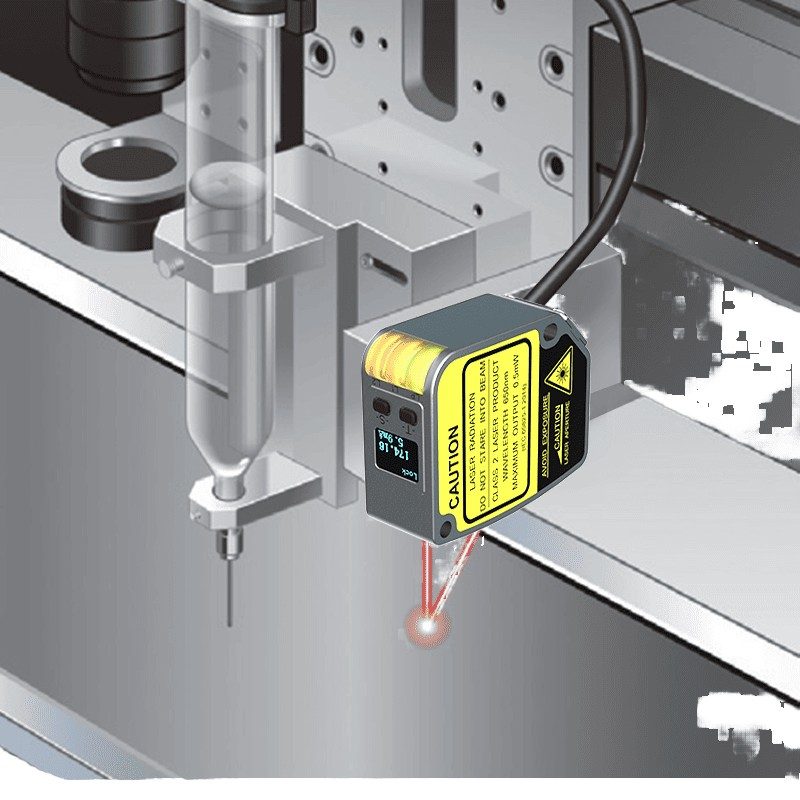

The journey toward exceptional accuracy begins with advanced sensing technologies. Optical sensors using laser interferometry, capacitive sensors measuring minute distance changes, and ultrasonic sensors detecting microscopic flaws—all work in concert to create manufacturing environments where variability becomes the exception rather than the rule. These technologies don’t just measure; they predict, compensate, and adapt in real-time, creating self-correcting production systems that continuously optimize their own performance.

Environmental factors that once plagued measurement consistency—temperature variations, vibration, electromagnetic interference—are now systematically neutralized through intelligent sensor design. Modern high-accuracy sensors incorporate built-in compensation algorithms, thermal stability controls, and vibration-dampening architectures that maintain precision even in the most challenging industrial environments. This resilience transforms sensor accuracy from a laboratory curiosity into a practical shop-floor reality.

The impact of improved sensor accuracy reverberates across entire supply chains. Manufacturers using high-precision sensors report significant reductions in material waste—often exceeding 30%—as production processes become more predictable and controlled. Quality-related recalls decrease dramatically, while customer satisfaction scores reach unprecedented levels. The financial implications are substantial: for many manufacturers, the investment in superior sensor technology pays for itself within the first year of operation through reduced waste and improved efficiency.

Looking toward the future, the evolution of sensor accuracy shows no signs of slowing. Emerging technologies like quantum sensing and AI-enhanced calibration promise to push measurement precision into previously unimaginable territories. These advancements will enable new manufacturing paradigms—from atomic-scale fabrication to real-time molecular analysis—that will redefine industrial production in the coming decades. The factories of tomorrow will be built not on steel and concrete, but on data and precision, with accurate sensors serving as their foundational elements.

For forward-thinking manufacturers, the message is clear: embracing high-accuracy sensor technology isn’t just about keeping pace with industry standards—it’s about defining them. In the precision economy, the most valuable currency isn’t speed or scale, but accuracy. Those who master this currency will not only lead their industries but will shape the very future of manufacturing itself.

Leave a Message