In the intricate world of industrial process control, water treatment, chemical manufacturing, and even advanced consumer appliances, one parameter stands as a silent sentinel of safety, efficiency, and quality: liquid level. The ability to measure this fundamental variable accurately and, more critically, consistently, is the bedrock upon which reliable operations are built. This is where the concept of Liquid Level Sensor Stability transcends from a technical specification to a pivotal operational philosophy. It’s not merely about getting a reading; it’s about getting the right reading—time after time, under pressure, amidst change, and without fail.

Stability in a liquid level sensor refers to its ability to maintain a consistent and accurate output signal over an extended period, despite fluctuations in environmental conditions, process variables, or simply the passage of time. An unstable sensor is a liability. It can cause false alarms, trigger unnecessary shutdowns, lead to overfilling or run-dry conditions, and result in product waste, energy inefficiency, and significant safety risks. In contrast, a sensor with exemplary stability operates as a trusted partner, providing a steady stream of reliable data that forms the backbone of automated control loops and informed decision-making.

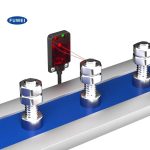

The journey to unparalleled stability begins with the core sensing technology. Different principles offer varying inherent stability profiles. For instance, advanced non-contact technologies like radar or ultrasonic sensors excel in stability as they are immune to the properties of the liquid (density, conductivity, dielectric constant) and avoid issues like coating, corrosion, or mechanical wear that plague contact sensors. Similarly, well-designed hydrostatic pressure sensors, when paired with high-stability piezoresistive chips and sophisticated temperature compensation algorithms, can deliver remarkable long-term drift performance, making them ideal for tank farm inventory management.

However, technology choice is only the first chapter. The true test of stability lies in a sensor’s resilience against real-world adversaries. Temperature swings are a primary destabilizer, causing materials to expand and contract and electronic components to drift. Top-tier sensors incorporate multi-point temperature compensation and use materials with matched thermal coefficients to neutralize this effect. Process noise—from agitators, pumps, or filling streams—can create turbulent surfaces or pressure waves that confuse a sensor. Advanced signal processing, like echo intelligence software in radar sensors or damping adjustments in pressure transmitters, is essential to filter out noise and lock onto the true level signal.

Furthermore, the chemical compatibility of wetted materials cannot be an afterthought. A sensor that degrades, coats, or corrodes will see its stability plummet. Selecting sensors with appropriate metallurgy (e.g., Hastelloy, Tantalum) or specialized coatings ensures the sensing element remains pristine, preserving its calibration and response over years of service. This is a direct investment in long-term stability and reduced total cost of ownership.

Ultimately, achieving bulletproof stability is a holistic endeavor. It requires a synergy of robust mechanical design, intelligent electronics, and smart software. Features like built-in diagnostics, predictive maintenance alerts, and easy, drift-free recalibration procedures empower users to not only achieve stability but sustain it throughout the sensor’s lifecycle. In an era of Industry 4.0 and the Industrial Internet of Things (IIoT), a stable sensor is more than a measuring device; it is a reliable data node, feeding trustworthy information into digital twins and analytics platforms, enabling true predictive control and operational excellence.

Therefore, when evaluating liquid level sensors, look beyond the basic accuracy figures. Scrutinize the long-term drift specs, the temperature compensation range, the ingress protection rating, and the manufacturer’s commitment to quality and testing. Demand stability. Because in the relentless flow of industrial processes, you need a measurement you can count on—not just a measurement you can read. Investing in superior Liquid Level Sensor Stability is investing in the very stability of your process, your product, and your peace of mind.

Leave a Message