In the world of industrial and chemical processing, the ability to accurately measure fluid flow is not just a convenience—it’s a necessity. However, harsh environments laden with corrosive substances can wreak havoc on standard equipment, leading to frequent failures, costly downtime, and compromised safety. This is where corrosion-resistant flow sensors step in, offering a revolutionary solution designed to withstand the most aggressive conditions while delivering precise and reliable measurements.

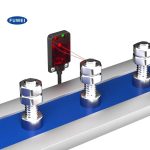

Corrosion-resistant flow sensors are engineered with advanced materials such as stainless steel, Hastelloy, titanium, or specialized polymers that provide exceptional resistance to chemical attack, oxidation, and erosion. These sensors are specifically tailored for industries where exposure to acids, alkalis, solvents, or saline solutions is commonplace. By integrating these robust materials, manufacturers ensure longevity and consistent performance, even in settings that would quickly degrade conventional sensors.

The applications for these durable sensors are vast and critical. In the chemical industry, they monitor the flow of aggressive reagents during production processes. In water treatment plants, they handle chlorinated water and other corrosive additives without faltering. The oil and gas sector relies on them to measure flow in pipelines where sour crude or other corrosive hydrocarbons are present. Additionally, pharmaceutical and food processing industries benefit from their ability to maintain hygiene and resist cleaning agents.

Beyond material selection, the design of corrosion-resistant flow sensors often incorporates features such as sealed electronics, non-intrusive measurement techniques, and smooth interior surfaces to prevent buildup and further enhance durability. Many modern variants also include smart technology, enabling real-time data monitoring, predictive maintenance alerts, and seamless integration with industrial IoT systems. This not only boosts operational efficiency but also reduces the total cost of ownership by minimizing unexpected repairs and replacements.

Investing in corrosion-resistant flow sensors is a proactive step toward enhancing operational reliability and safety. By choosing sensors built to endure challenging environments, companies can avoid the pitfalls of equipment failure, ensure regulatory compliance, and maintain uninterrupted productivity. As technology continues to evolve, these sensors are set to become even more integral to industrial automation, providing smarter, more resilient solutions for the future.

In conclusion, corrosion-resistant flow sensors represent a vital innovation for industries operating under demanding conditions. Their ability to combine rugged durability with high accuracy makes them an indispensable tool for achieving efficiency, safety, and long-term savings. Embracing this technology is not just an upgrade—it’s a strategic move toward sustainable and resilient operations.

Leave a Message