As the global shift toward Industry 4.0 accelerates, industrial sensors are no longer just input devices—they’re becoming intelligent data nodes, capable of driving real-time decisions, machine learning, and autonomous manufacturing. From high-speed production lines to AI-driven robots, smart sensors are shaping the future of industrial automation and digital transformation.

In this post, we’ll explore the evolving role of sensors in the age of Industry 4.0, the technologies enabling next-generation sensing, and why investing in smart sensor infrastructure is key to staying competitive.

As the global shift toward Industry 4.0 accelerates, industrial sensors are no longer just input devices—they’re becoming intelligent data nodes, capable of driving real-time decisions, machine learning, and autonomous manufacturing. From high-speed production lines to AI-driven robots, smart sensors are shaping the future of industrial automation and digital transformation.

In this post, we’ll explore the evolving role of sensors in the age of Industry 4.0, the technologies enabling next-generation sensing, and why investing in smart sensor infrastructure is key to staying competitive.

What Are Smart Industrial Sensors?

Traditional sensors collect and transmit basic data (such as proximity, pressure, or temperature). In contrast, smart Industrial sensors are equipped with built-in microprocessors, diagnostics, and communication capabilities. They don’t just sense—they also analyze, communicate, and adapt. Modern smart sensors can:- Pre-process data locally (edge computing)

- Communicate via digital protocols like RS485, IO-Link, Modbus, EtherCAT

- Monitor their own performance and report faults

- Integrate with MES, ERP, and cloud-based systems

Key Trends Shaping the Future of Industrial Sensing

1. AI-Enhanced Sensing

With sensors collecting vast amounts of real-time data, artificial intelligence (AI) algorithms are being used to detect patterns, predict failures, and suggest improvements. For example, a laser displacement sensor could alert maintenance teams when vibration patterns indicate bearing wear—before failure occurs.2. Miniaturization & High Precision

As space becomes a premium on smart machines, sensors are becoming smaller, faster, and more accurate. FUWEI’s latest laser triangulation sensors, for instance, offer sub-10μm precision in a compact package, ideal for electronics and semiconductor applications.3. Predictive Maintenance

Smart sensors continuously monitor critical machine parameters. Combined with cloud analytics, they help manufacturers shift from reactive to predictive maintenance, reducing unplanned downtime and extending asset life.4. Wireless and Energy-Efficient Sensing

Battery-powered wireless sensors with low energy consumption (LoRaWAN, Zigbee, NB-IoT) are enabling remote condition monitoring in hard-to-reach or mobile industrial environments.5. Seamless Integration with Digital Ecosystems

Smart sensors are now plug-and-play with PLCs, SCADA, and industrial IoT platforms. Using standardized protocols like IO-Link or OPC UA, they deliver real-time data to dashboards, cloud storage, or AI engines.Applications of Smart Sensors in Industry 4.0

- Automated Quality Control – Sensors detect tiny defects in surface finish, dimension, or color in real time.

- Collaborative Robotics (Cobots) – Force and distance sensors ensure safe, precise human-machine cooperation.

- Digital Twins – Real-time sensor data powers virtual models of machines for simulation and optimization.

- Energy Monitoring – Voltage, current, and thermal sensors optimize energy usage and reduce carbon footprint.

- Smart Logistics – Ultrasonic and RFID sensors manage warehouse inventory, shelf levels, and AGV navigation.

Why FUWEI Sensors Are Ready for the Future

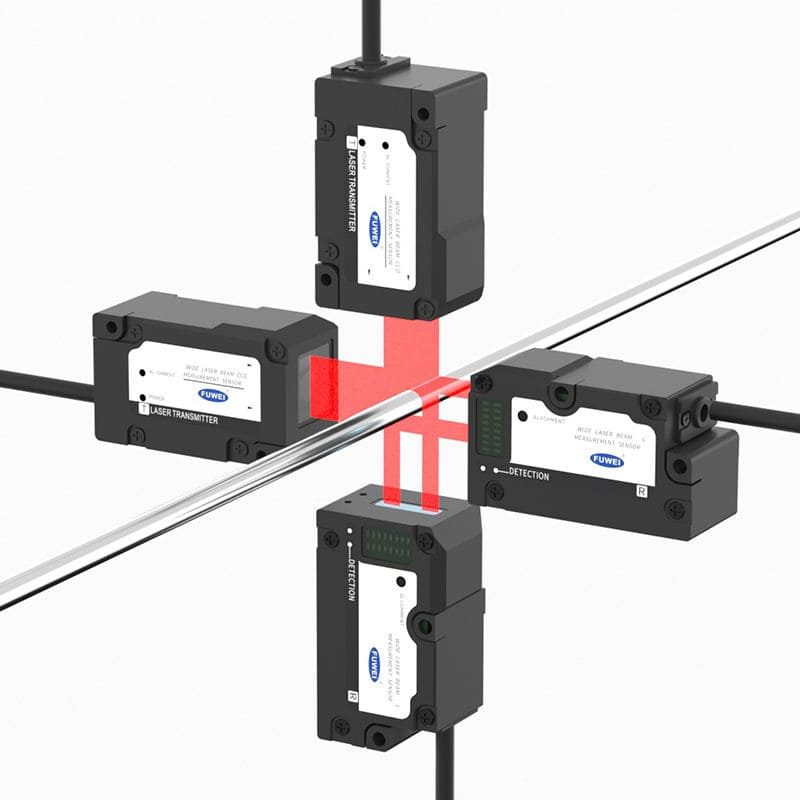

At FUWEI, we are building the future of industrial sensing—today. Our line of high-precision, smart-enabled sensors includes:- ✔ Laser Displacement Sensors with RS485 and Modbus

- ✔ Ultrasonic Sensors with long-range detection and rugged IP67 protection

- ✔ Photoelectric Sensors with self-diagnostics and high-speed response

- ✔ Custom OEM Solutions for edge AI, IoT, and wireless sensor applications

How to Start Your Sensor-Driven Transformation

To begin your smart factory journey, ask these questions:- ✅ What real-time data would improve your decision-making?

- ✅ Can your current equipment support digital sensor communication?

- ✅ Are there critical machines that could benefit from predictive analytics?

- ✅ Do you need compact, high-speed, or harsh-environment sensor options?

Final Thoughts

Industrial sensors are evolving from passive components to intelligent agents of change. In the era of Industry 4.0, sensors don’t just report—they think, learn, and act. Investing in smart sensing infrastructure today will unlock the full potential of automation, AI, and digital transformation tomorrow. Choose FUWEI as your partner in this evolution. Together, we can build intelligent, adaptive, and future-ready industrial systems.Tags: smart Industrial sensors, Industry 4.0 sensors, AI in automation, sensor integration, FUWEI smart sensors, predictive maintenance, digital factory

Leave a Message