Industrial sensors are critical components in automated manufacturing, quality control, and process monitoring. To keep your production running smoothly, it’s essential to maintain sensors properly. Regular maintenance ensures consistent accuracy, reduces unexpected downtime, and prolongs the sensor’s service life.

In this article, we share practical industrial sensor maintenance tips that help you protect your investment and optimize your factory automation systems.

Industrial sensors are critical components in automated manufacturing, quality control, and process monitoring. To keep your production running smoothly, it’s essential to maintain sensors properly. Regular maintenance ensures consistent accuracy, reduces unexpected downtime, and prolongs the sensor’s service life.

In this article, we share practical industrial sensor maintenance tips that help you protect your investment and optimize your factory automation systems.

Why Sensor Maintenance Matters

Industrial sensors operate in harsh environments — exposed to dust, moisture, vibration, and temperature fluctuations. Over time, sensor performance may degrade due to:- Accumulation of dirt and debris on sensing surfaces

- Mechanical wear or damage

- Electrical connection corrosion or looseness

- Calibration drift

Top 6 Maintenance Tips for Industrial Sensors

1. Regular Cleaning

Keep sensor lenses, probes, and surfaces clean from dust, oil, or residue. Use lint-free cloths and manufacturer-recommended cleaning agents. Avoid abrasive materials that may scratch sensor surfaces.2. Periodic Calibration

Verify sensor accuracy by following calibration schedules recommended by manufacturers. Use calibration tools or reference standards to adjust sensor outputs if drift is detected.3. Inspect Electrical Connections

Check for loose wires, corrosion, or damaged connectors. Secure and replace any faulty connections to ensure signal integrity.4. Monitor Environmental Conditions

Ensure sensors are operating within specified temperature, humidity, and vibration limits. Consider protective housings or enclosures for harsh environments.5. Firmware and Software Updates

For smart sensors with embedded processors, keep firmware up to date to benefit from bug fixes and improved functionality.6. Document Maintenance Activities

Maintain records of inspections, calibrations, and repairs. This helps track sensor performance trends and plan future maintenance proactively.Common Sensor Types and Their Maintenance Needs

| Sensor Type | Key Maintenance Action |

|---|---|

| Laser Displacement Sensors | Keep optics clean; check calibration regularly |

| Ultrasonic Sensors | Clean sensor face; inspect for moisture ingress |

| Photoelectric Sensors | Clean lenses; verify emitter and receiver alignment |

| Proximity Sensors | Inspect mounting; check for metal debris buildup |

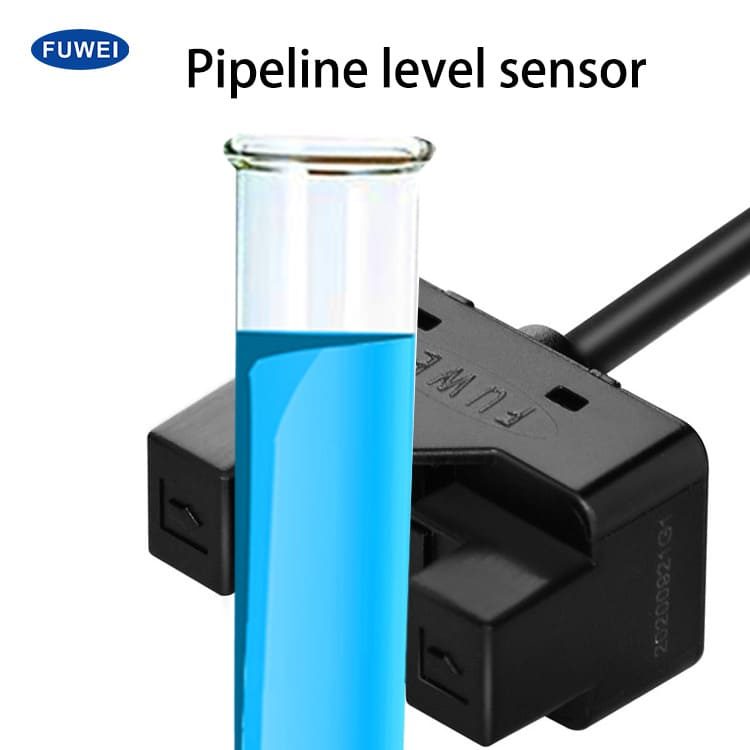

FUWEI’s Commitment to Quality and Support

At FUWEI, we understand that sensor maintenance is vital for long-term success. That’s why our products come with detailed maintenance guides and access to technical support worldwide. Our durable Industrial sensors are designed for easy installation and low maintenance, helping you minimize total cost of ownership while maximizing uptime.Contact FUWEI for Reliable Sensor Solutions

Need help selecting sensors with easy maintenance or want advice on sensor care for your specific application? Our experts are ready to assist. Get in Touch with FUWEI Sensor Experts →Conclusion

Proper maintenance of industrial sensors is key to ensuring precision, reliability, and operational continuity in automated systems. By following simple yet effective maintenance practices, you can avoid costly downtime and extend the lifespan of your sensors. Partner with FUWEI for high-quality sensors backed by comprehensive support to keep your automation running flawlessly.Tags: industrial sensor maintenance, sensor calibration, sensor reliability, factory automation maintenance, FUWEI sensors

Leave a Message