In the pulsating heart of modern industry, where data is the new currency, Industrial sensors stand as the silent sentinels. They are the eyes, ears, and fingertips of automation, translating physical phenomena into actionable intelligence. Yet, their performance is not eternal. The concept of Industrial Sensor Lifespan is a critical, often underestimated, pillar of operational excellence and total cost of ownership. It’s not merely about a device failing; it’s about the cascading effect of unplanned downtime, compromised quality, and safety risks. Moving beyond a simple countdown to failure, a proactive strategy to maximize sensor longevity is a direct investment in resilience and profitability.

So, what dictates the lifespan of these vital components? It is a complex equation where environmental stressors are the primary variables. Extreme temperatures can cause material fatigue and electronic drift. Humidity and condensation invite corrosion and short circuits. Particulate matter, from abrasive dust to oily mists, can clog or coat sensitive elements. Constant vibration and mechanical shock can loosen connections and damage internal structures. Even the very process they monitor—be it aggressive chemicals, high-pressure fluids, or electromagnetic interference—can accelerate wear. Understanding these factors is the first step in selecting the right soldier for the battle.

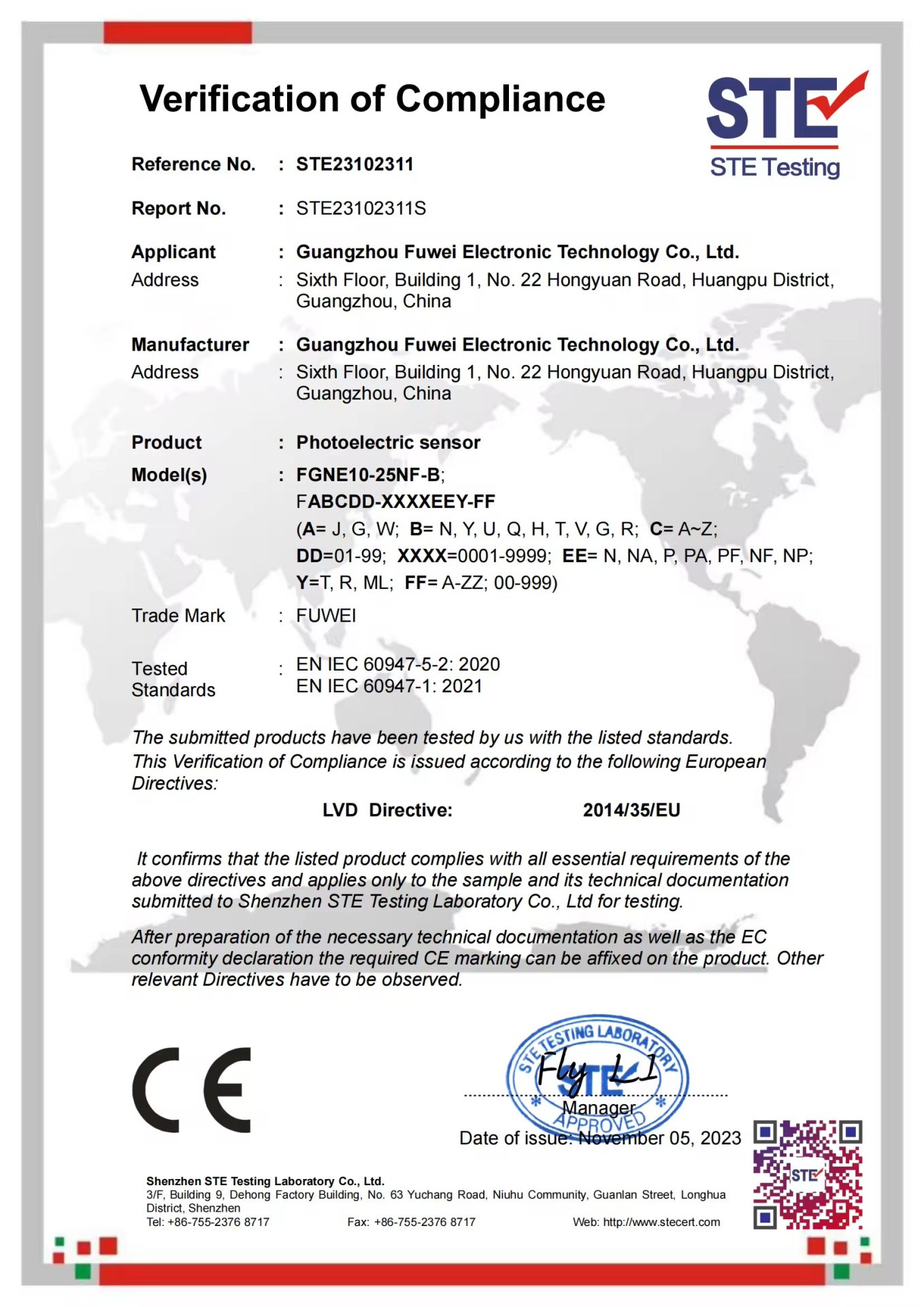

Maximizing lifespan begins long before installation, with strategic selection. The mantra ‘fit for purpose’ has never been more relevant. Investing in sensors with robust ingress protection (IP) ratings, constructed from materials like stainless steel or specialized polymers resistant to process media, pays long-term dividends. Consider sensors with built-in diagnostics and self-monitoring capabilities; they don’t just measure the process, they report on their own health, providing early warnings of degradation. Furthermore, leveraging modern communication protocols like IO-Link offers not only data but detailed parameterization and condition monitoring, transforming a simple device into an intelligent asset.

Proper installation and commissioning are the bedrock of longevity. A sensor perfectly specified can be doomed by poor practices. Following manufacturer guidelines for mounting, torque settings, and cable routing is non-negotiable. Protecting cables with conduits in high-traffic areas, ensuring proper grounding to avoid electrical noise, and calibrating the sensor correctly for its specific application are all crucial. This phase sets the trajectory for the sensor’s entire service life, preventing premature failures from misalignment, stress, or signal integrity issues.

The journey continues with a disciplined regime of proactive maintenance. This transcends reactive replacement. Scheduled inspections for physical damage, buildup, or corrosion should be standard. Regular calibration checks, traceable to international standards, ensure the sensor not only works but works accurately. Utilizing predictive maintenance tools, which analyze trends in sensor output or diagnostic data, can identify anomalies like increasing drift or response time lag, allowing for planned intervention during a maintenance window, not during a production crisis.

When failure is inevitable, strategic obsolescence management takes center stage. A well-maintained sensor with a documented history provides valuable data for root cause analysis. Was it a generic wear-out, or a specific, repeatable environmental attack? This intelligence informs future selection and even process improvements. Furthermore, partnering with suppliers who offer long-term availability of spares, repair services, or upgrade paths protects your investment and prevents costly system redesigns down the line.

In essence, viewing Industrial Sensor Lifespan as a manageable asset, rather than a fixed expiration date, unlocks a new level of operational control. It’s a holistic philosophy encompassing smart selection, meticulous installation, vigilant maintenance, and learned evolution. By championing this approach, plants do more than just avoid unexpected stoppages. They build a foundation of reliable, high-fidelity data, ensure consistent product quality, enhance workplace safety, and ultimately, secure a formidable competitive advantage in an increasingly automated world. The goal is not immortality, but predictable, optimized, and cost-effective service—where every sensor delivers its full potential, for every possible moment.

Leave a Message