In the complex ecosystem of modern logistics and supply chain management, warehouse temperature sensors have emerged as silent guardians of product quality and safety. These unassuming devices work tirelessly behind the scenes, monitoring environmental conditions and ensuring that temperature-sensitive goods remain within specified parameters. From pharmaceuticals to perishable foods, electronics to chemicals, maintaining optimal temperature conditions isn’t just about quality assurance—it’s about protecting consumer safety, reducing waste, and preserving millions of dollars in inventory value.

The evolution of warehouse temperature monitoring has been nothing short of revolutionary. Gone are the days when warehouse managers relied on manual temperature checks and paper logs. Today’s smart sensors provide real-time monitoring, automated alerts, and comprehensive data analytics that transform how businesses approach inventory management. These advanced systems can detect even the slightest temperature fluctuations, allowing for immediate corrective action before products become compromised.

Modern temperature sensors come in various forms, each designed for specific applications and environments. Wireless IoT sensors have particularly transformed warehouse monitoring by eliminating the need for complex wiring installations. These devices can be strategically placed throughout a facility, creating a comprehensive monitoring network that covers every corner of the storage space. Some advanced models even feature self-calibration capabilities and can operate for years on a single battery, significantly reducing maintenance requirements.

The integration of artificial intelligence and machine learning has taken temperature monitoring to unprecedented levels of sophistication. Smart systems can now predict potential temperature deviations based on historical data, external weather patterns, and equipment performance metrics. This predictive capability enables proactive maintenance of refrigeration systems and helps prevent temperature excursions before they occur. The result is a dramatic reduction in product loss and improved operational efficiency.

For businesses operating in regulated industries like pharmaceuticals and food processing, temperature sensors are more than just convenience tools—they’re compliance necessities. Regulatory bodies worldwide have established strict guidelines for temperature monitoring and documentation. Advanced sensor systems automatically generate compliance reports and maintain detailed audit trails, simplifying regulatory compliance and reducing the administrative burden on warehouse staff.

The economic impact of implementing robust temperature monitoring systems cannot be overstated. According to industry estimates, temperature-related spoilage costs businesses billions annually. By preventing even a small percentage of this loss, temperature sensors deliver substantial return on investment. Additionally, the data collected by these systems helps optimize energy consumption in climate-controlled areas, further reducing operational costs.

Looking toward the future, warehouse temperature sensors are poised to become even more intelligent and integrated. The emergence of 5G technology promises faster data transmission and lower latency, while edge computing capabilities will enable real-time decision-making at the sensor level. We’re also seeing the development of multi-parameter sensors that monitor not just temperature, but also humidity, light exposure, and vibration—providing a complete picture of storage conditions.

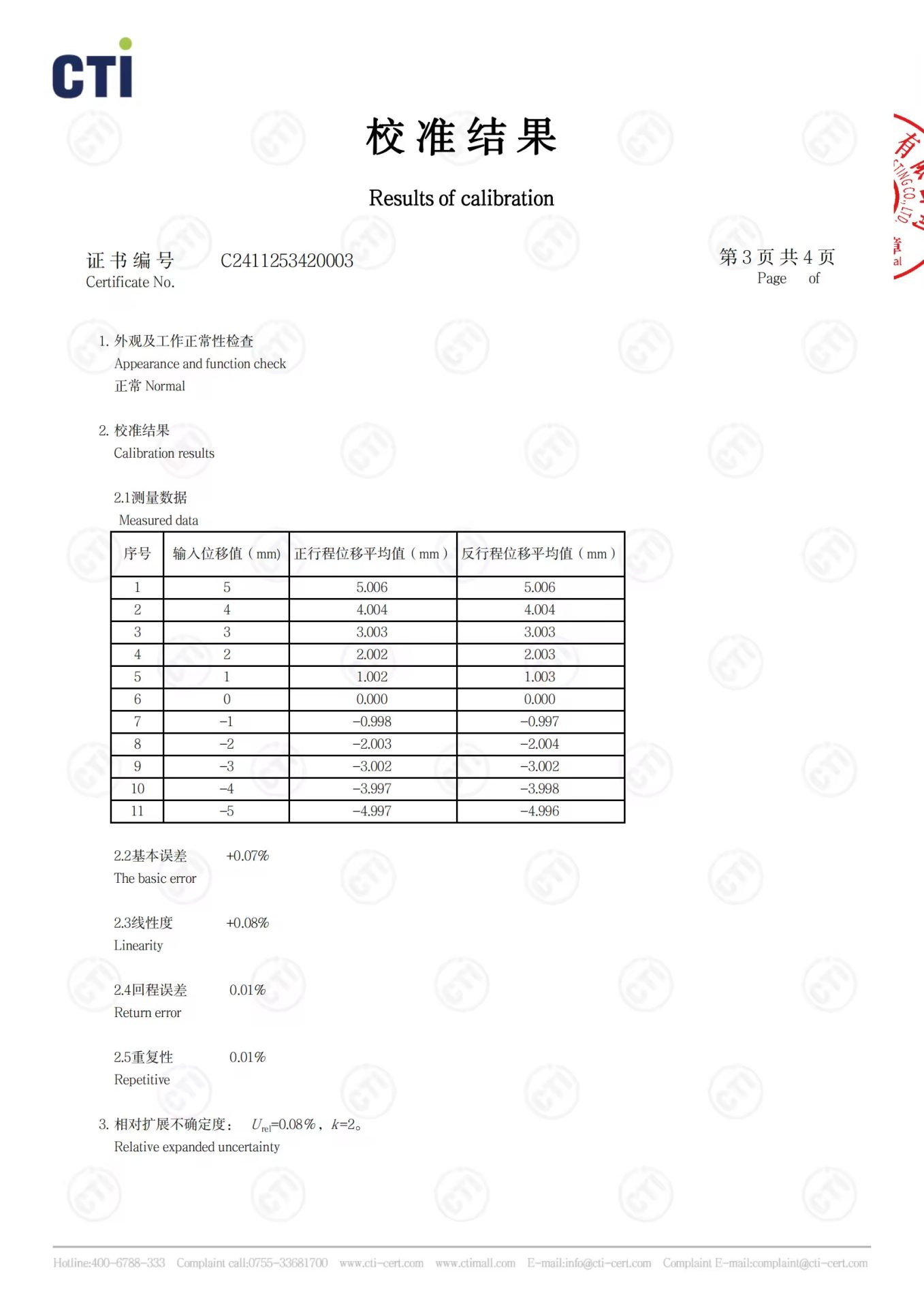

Implementation best practices involve strategic sensor placement, regular calibration, and comprehensive staff training. Sensors should be positioned in areas most susceptible to temperature variations, near doors, loading docks, and ventilation systems. Regular maintenance and calibration ensure accuracy, while proper training empowers staff to respond effectively to alerts and interpret monitoring data correctly.

As global supply chains become increasingly complex and consumer expectations for product quality continue to rise, the role of warehouse temperature sensors will only grow in importance. These technological marvels represent a critical intersection of innovation and practicality, delivering tangible benefits that extend from the warehouse floor to the end consumer. For forward-thinking businesses, investing in advanced temperature monitoring isn’t just an operational decision—it’s a strategic imperative that supports quality, safety, and sustainability objectives.

Leave a Message