In the heart of modern industrial operations, where precision meets extreme conditions, a quiet revolution is unfolding. Industrial low-temperature sensors have emerged as unsung heroes, transforming how industries monitor, control, and optimize processes in sub-zero environments. These sophisticated devices are no longer mere accessories but fundamental components driving efficiency and innovation across sectors from pharmaceuticals to aerospace, from food processing to cryogenic research.

The evolution of industrial temperature monitoring has been nothing short of remarkable. Traditional sensors struggled with accuracy and reliability when temperatures plunged below freezing, often delivering inconsistent readings or failing entirely. Today’s advanced low-temperature sensors, however, thrive in these challenging conditions, maintaining precision at temperatures as low as -200°C and beyond. This technological leap has opened new frontiers in industrial applications that were previously constrained by measurement limitations.

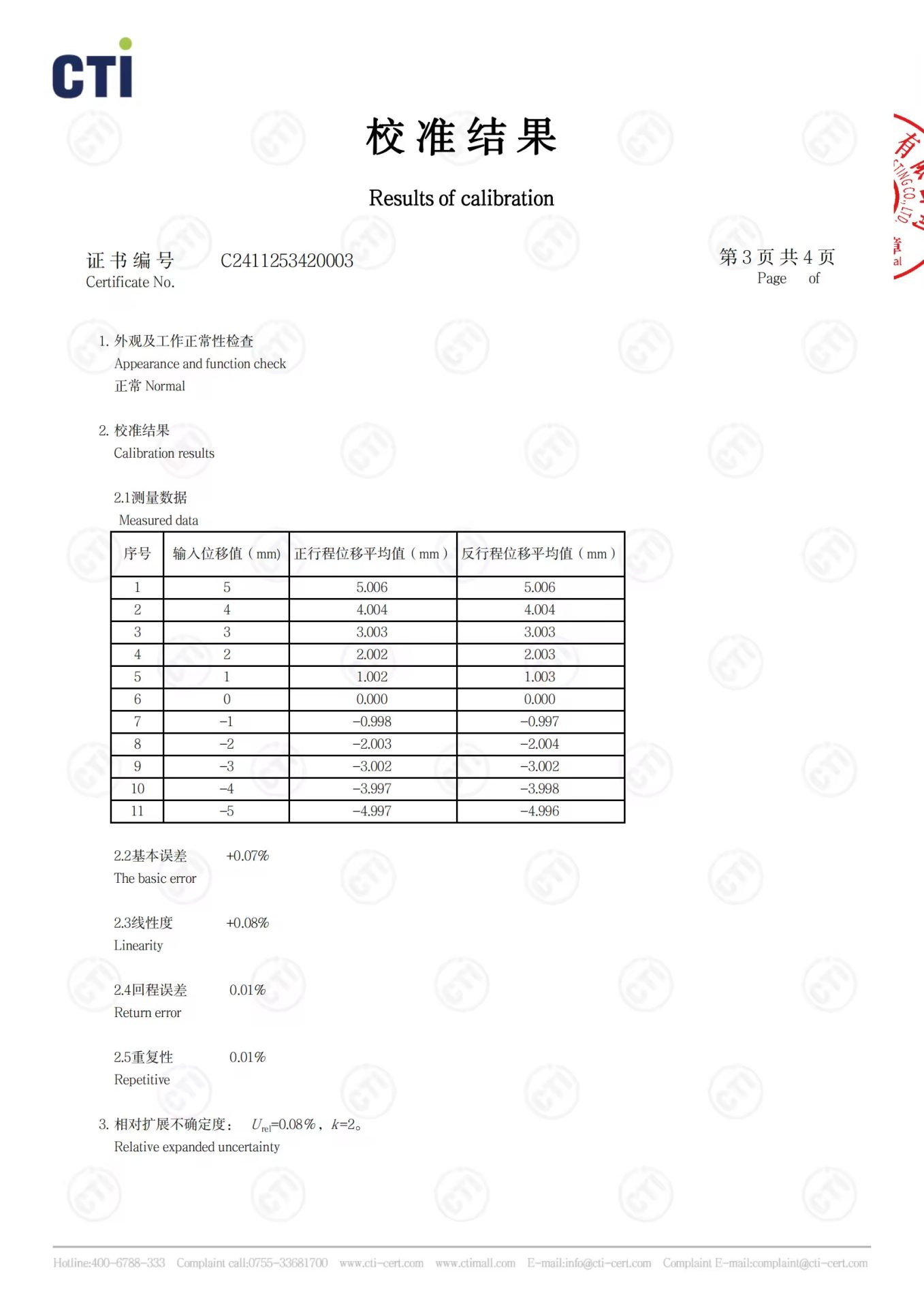

What sets modern industrial low-temperature sensors apart is their sophisticated engineering and material science. Manufacturers have developed specialized sensing elements using materials that maintain their electrical properties even in extreme cold. Advanced semiconductor technology, combined with innovative packaging designs, ensures these sensors can withstand thermal shock, condensation, and mechanical stress while delivering accurate, real-time data. The integration of smart calibration algorithms further enhances their precision, automatically compensating for environmental variables that could affect readings.

The applications of these technological marvels span across critical industries. In pharmaceutical manufacturing, low-temperature sensors monitor cryogenic storage for vaccines and biological materials, ensuring the integrity of life-saving medications. The food processing industry relies on them to maintain precise temperature control during flash freezing and cold chain logistics, preserving quality and safety from production to consumption. In energy sectors, they monitor liquefied natural gas (LNG) facilities and superconducting systems, while aerospace applications include monitoring rocket fuel systems and satellite components.

Modern industrial low-temperature sensors are increasingly becoming intelligent components within larger ecosystems. The integration of IoT connectivity and Industry 4.0 capabilities has transformed these devices from simple measurement tools into proactive monitoring systems. They can now communicate with central control systems, predict maintenance needs, and automatically adjust industrial processes based on real-time temperature data. This connectivity enables remote monitoring of multiple locations, predictive analytics for preventive maintenance, and seamless integration with automated control systems.

Reliability and durability form the cornerstone of industrial low-temperature sensor design. Manufacturers subject these devices to rigorous testing protocols, simulating years of operation in extreme conditions. Environmental testing includes exposure to rapid temperature cycling, high humidity, vibration, and electromagnetic interference. This thorough validation process ensures that when these sensors are deployed in critical applications—whether monitoring superconducting magnets in MRI machines or controlling industrial freezing processes—they perform consistently and reliably.

The economic impact of advanced low-temperature sensing technology extends far beyond the initial investment. By providing precise temperature control, these sensors help industries reduce energy consumption, minimize product loss, and optimize process efficiency. In cryogenic applications, even minor temperature fluctuations can have significant consequences, making accurate monitoring crucial for both operational efficiency and product quality. The data collected by these sensors also enables better process optimization, leading to reduced waste and improved overall equipment effectiveness.

As industries continue to push the boundaries of what’s possible in extreme environments, the future of industrial low-temperature sensors looks increasingly promising. Emerging technologies like quantum sensing and nanotechnology are paving the way for even more sensitive and robust temperature measurement solutions. Researchers are developing sensors capable of operating at near-absolute zero temperatures, opening possibilities for quantum computing and advanced physics research. Meanwhile, improvements in wireless technology and energy harvesting are making these sensors more versatile and easier to deploy in remote or hazardous locations.

The selection and implementation of industrial low-temperature sensors require careful consideration of multiple factors. Engineers must evaluate temperature range requirements, accuracy specifications, response times, environmental conditions, and compatibility with existing systems. Proper installation and calibration are equally crucial, as incorrect placement or inadequate thermal coupling can compromise measurement accuracy. Leading manufacturers now provide comprehensive support, from initial consultation through installation and ongoing maintenance, ensuring optimal performance throughout the sensor’s lifecycle.

In conclusion, industrial low-temperature sensors represent a critical enabling technology for modern industry. Their ability to provide reliable, accurate temperature measurements in extreme conditions has become indispensable across numerous sectors. As technology continues to advance, these sensors will play an increasingly vital role in enabling new industrial processes, improving efficiency, and driving innovation. For industries operating at the cold edge of technology, investing in advanced low-temperature sensing solutions isn’t just about maintaining temperature—it’s about unlocking new possibilities for growth and innovation in an increasingly competitive global market.

Leave a Message